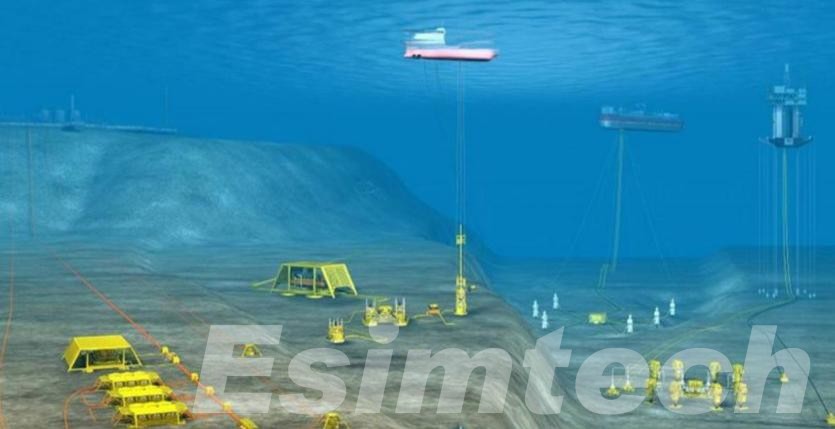

At the recent Deepwater Oil and Gas Development Forum, ESIMTECH captured the attention of energy leaders and engineers by showcasing their advanced subsea production systems through stunning 3D holography. This immersive visual technology provided a realistic and interactive representation of how these integrated subsea systems function flawlessly at depths exceeding 1,000 meters beneath the ocean’s surface.

The highlight of the exhibit was a full-scale holographic simulation of ESIMTECH’s proprietary subsea infrastructure, including intelligent subsea trees, high-efficiency multiphase pumps, and electric-hydraulic control modules. The dynamic display allowed attendees to witness real-time remote operation of each component under the simulated pressure and current conditions of deep-sea geology.

Precision Control in Harsh Deepwater Environments

The showcased intelligent subsea trees represent a significant advancement in offshore oil field automation. Each tree is embedded with real-time sensors and linked to a centralized electric-hydraulic control unit, allowing operators to adjust flow rates, open or close valves, and monitor pressure—all remotely. This reduces human intervention in hazardous conditions, enhancing both safety and operational efficiency.

Equally impressive were ESIMTECH’s multiphase pumps, which optimize the extraction of oil, gas, and water mixtures from the seabed. These pumps are designed to handle complex flow regimes and variable viscosities typical of deep-sea fields, sustaining high throughput even in challenging reservoir conditions.

Case Study: Boosting Recovery Efficiency in the South China Sea

During the forum, ESIMTECH engineers shared a case study of their subsea systems deployed in a 1,200-meter-deep block of the South China Sea. Utilizing integrated electric-hydraulic controls, operators were able to fine-tune equipment in real time without deploying deepwater ROVs. As a result, oil recovery efficiency improved by 18% while intervention risks were significantly reduced.

This installation marked one of the few successful deployments of smart subsea production systems in a geologically complex environment, with unpredictable currents and sediment shifts. The system’s adaptive automation ensured uninterrupted flow even during seasonal disturbances, maintaining production continuity and protecting asset longevity.

Innovating the Future of Subsea Systems

ESIMTECH’s presentation at the Deepwater Forum emphasized not only the reliability of their subsea systems, but also their vision for next-gen offshore innovation. Future upgrades in progress include AI-based flow prediction, autonomous fault diagnosis, and deep-learning algorithms for adaptive control logic.

These advancements aim to make subsea operations more autonomous, further reducing the need for surface intervention. ESIMTECH’s deep expertise in subsea production systems and engineering design places them at the forefront of digital transformation in offshore energy.

By integrating 3D holographic technology with cutting-edge engineering, ESIMTECH continues to push the boundaries of what’s possible in subsea systems. Their showcase at the Deepwater Oil and Gas Development Forum underscored their commitment to safe, efficient, and smart energy solutions. For more information about ESIMTECH’s solutions and innovations in subsea production systems, visit their official resource on subsea technology here.